Renewable Energy

The greenhouse effect and thereby resulting climate change has initiated an on-going debate about how to reduce the emission of CO2. Energy has to be used through either regeneration, alternative and/or renewable methods.

As from the year 2000, power stations had to be climate-friendly bringing on the so-called Energy Revolution and the necessity for new individual and client-specific special constructions but also new processes.

Even when efficiency and economy cannot keep pace with traditional processes from coal to electricity, subsidies and the tightening of the German Federal Emission Control Act have in fact paved the way for a positive situation for the realisation of new technologies and process sequences.

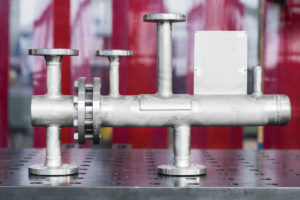

TUBE-TEC cooperates closely along these lines, in which we collaborate with our clients in industry, especially in the areas of research and process development, developing pressurised components, tube coil systems and vessels – often even with new geometries – from prototypes in a pilot plant until they are ready to go into production.

Whether heat exchange processes for Bio-ethanol manufacture or Bio-diesel production (fermentation, distillation and condensation) or for evaporators, super-heaters and condensers for solar technology – TUBE-TEC fabrication know-how is part & parcel of many of these technologies.

APPLICATION EXAMPLES

- Bio-ethanol manufacture (heat exchanger processes for fermentation, distillation and condensation)

- Bio-diesel production (heat exchanger processes for esterification, thermal/mechanical separations)

- Evaporators, super-heaters, condensers and further components for solar technology, geo-thermics and co-generation plant (combined heat & power units)

- In general: heat exchangers in the widest sense

- In general: waste heat recovery / cooling processes / process heat supply / thermal oil heaters